-

The company of the future

AUTHOR Susanne Schröder

(© Hanser/Schröder)A traditional handcraft operation on the path to industrial manufacturing: Der Karl Walter Formen- und Kokillenbau undergoes restructuring. The owner and consultant explain how the changes are being made and why "simple tools" are used.

Company

Karl Walter Formen- und Kokillenbau GmbH & Co. KG

Location

Göppingen, Germany

Focus

Establishing an end-to-end process solution

Benefits:

- Tool standardization

- Transparency in planning and manufacturing

- Flexible, well-thought-out processes

Sector

Die manufacturing

Published

2018

Interviewee: Jens Buchert, Managing director

Dr. Jens Buchert, owner and Managing Director of Karl Walter Formen- und Kokillenbau GmbH & Co. KG in Göppingen, Germany, arranges pieces of paper on a large architectural drawing. The diagram shows the 3,000 m2 production building, with each machine represented by a piece of paper. The building layout is now being refined. Wait a minute: Weren't we going to talk about the company of the future? Is this really Industry 4.0? Not exactly, but the picture makes sense. Because it describes very well how Walter Formenbau is proceeding and the restructuring process it’s undergoing. Many small steps are necessary to reach the goal, because they’re undertaking nothing less than a complete transformation. Jens Buchert and Jens Lüdtke from Tebis Consulting took the Form+Werkzeug magazine editors along on a tour of the plant and presented their vision for the die manufacturing company of the future.

Background

Walter Formenbau was founded in 1960 and currently has 40 employees. The company is among the leading manufacturers of molds for aluminum hubs and castings for the automotive sector. Various milling and turning machines are operating in the 3,000 m2 production building, including 3- and 5-axis machining centers from Röders, Hermle and DMG Mori. Walter was family-owned for 56 years before Buchert acquired the company in November of 2016.

He has a doctorate in Mechanical Engineering and previously worked at a number of companies, including automotive manufacturers, software companies, prototype manufacturers and consulting. He's always been interested in manufacturing optimization and Industry 4.0.

So how did he come to buy a die manufacturing company? "I want to shape my own future, not just follow what others decide. And in Walter Formenbau I saw the opportunity to implement concepts that I’d already been thinking about for a long time."

The appeal of Walter Formenbau:It was a healthy handcraft operation with a good product and customer base.

The manufacture of gravity die-casting molds entails the construction of very similarly designed parts – an ideal starting point for standardization.

The dimensions of the modern office building and the production building are designed to enable planning far into the future.Before Buchert even set foot in the factory, he contacted an old acquaintance: Jens Lüdtke from Tebis AG. In addition to having been colleagues for years at Tebis, the two share a common vision of the die manufacturing company of the future. As head of Tebis Consulting, Lüdtke has 20 years of experience in the industry. In addition to commercial and production expertise, he has a high degree of process expertise in die, mold and model manufacturing.

Buchert discussed with him whether his vision could be implemented at Walter Formenbau, and it quickly became clear: Yes, Lüdtke also saw its great potential. If Buchert acquired the company, Lüdtke would provide advice and support. Why did Buchert decide on Tebis Consulting? “I’ve gotten to know many large consultant firms during my career," he says. "These people are perfect in business administration. They know right away what happens to the hourly rate if we double our spindle run time. But they can't tell me how to double spindle run time – and that's exactly where Tebis can score with its industry expertise."The consultant asks questions, researches and facilitates

As an industry expert, Lüdtke performs multiple tasks:

- Analyzing the current situation with its strengths and weaknesses as the basis for all of his planning steps

- Supporting the search for partners (for setup equipment, machines, tools and software tools) so that everything is compatible

- Checking commercial performance indicators and support for defining sales and investment goals

- Developing a detailed step-by-step plan and supporting implementation

- Serving as a partner for all individual elements of the overall plan: There's no saying "That's not my job."

- Checking for financial support options and assistance with preparing applications

"We have a great opportunity to create something in this company that never existed before," says Lüdtke. The consultants have already optimized parts of the manufacturing process in many companies, but the Tebis experts are enthusiastic about the all-encompassing scope at Walter and the associated opportunities to influence the overall concept. At the same time, the consultants were faced with a significant challenge: All the investment funds had to be generated from the company's own resources. Lüdtke: "We therefore started the milestones at the point where money is made: right where the tool meets the part."An extensive program like this sounds like it would require a large consulting budget. "Many of the companies we consult with have between 20 and 100 employees," explains Lüdtke. "None of them have large budgets for consulting. When we develop concepts, we do what’s possible for each company. We’ve developed a procedure that enables us to very quickly delve deep into a company's procedures."

Building a viable die manufacturing company for the future: Dr. Jens Buchert, owner and Managing Director of Karl Walter Formen- und Kokillenbau. (© Hanser/Schröder)

Building a viable die manufacturing company for the future: Dr. Jens Buchert, owner and Managing Director of Karl Walter Formen- und Kokillenbau. (© Hanser/Schröder)Milestones for the first 24 months

Tebis Consulting developed eight milestones for Walter Formenbau: Responsibilities, sequences and individual work steps are precisely defined for each process.

- 2.5D process: external CAM programming on Tebis, tool standardization, no manual reworking

- 3D process: external CAM programming on Tebis, 3D designs are assigned colors and features

- Paperless manufacturing: viewers are installed on the machines, milling documentation reduced, expenditures for drawing creation reduced by 50 percent

- Setup process: new setup process with FCS system introduced, setup logic integrated in the design, external setup areas implemented

- Planning and control: preliminary project completed for ERP and MES introduction, planning running smoothly using Excel tables

- ERP and MES: ERP is selected and installed, BDE and MDE are installed and communicate with MES and ERP, ProLeis PDM and MES are installed and are used throughout

- Automation of wheel rim die casting molds: 6,000 spindle hours were achieved on a machining center; the entire process is automated from order receipt to the finish-milled part

- Integration of future-oriented technology: augmented-reality pilot project is implemented, measuring on the machine and software-supported tool management are implemented.

In the middle of manufacturing: The new CAM office (in the white box) was located close to the machines. (© Hanser/Schröder)

In the middle of manufacturing: The new CAM office (in the white box) was located close to the machines. (© Hanser/Schröder)In the beginning was the chart

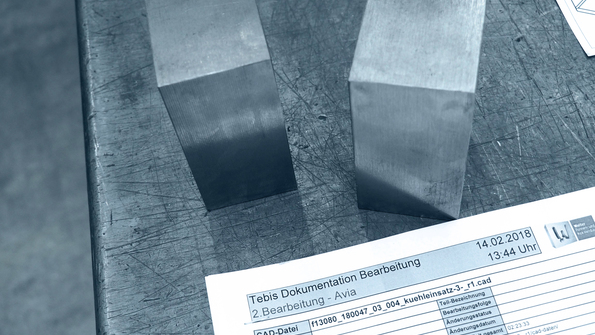

Tracking cards right from the start: All manufacturing steps are documented for each part for several months. (© Hanser/Schröder)

Tracking cards right from the start: All manufacturing steps are documented for each part for several months. (© Hanser/Schröder)The consulting process started with a large chart: Lüdtke and Buchert's team used this to compile all the elements needed for a die manufacturing company of the future. What do we want to achieve? Where do we want to be in five years? What investments are planned? What measures have what priority? How many employees and with what qualifications are needed? And the most important question: How can we at the same time keep our daily business running and making money so that we can also afford the investments? The rough outline then served as the basis for detailed planning.

A roadmap was developed with eight major milestones (see list on previous page). Targets were also defined for revenues, investments and machine runtimes. The work by Tebis started with the analysis of the current situation: The process experts spent two days at the company documenting workflows and processes. "We don't conduct individual interviews. Instead, we select a group of programmers, for example. This way we don't just get subjective opinions from an individual, but rather an overall perspective of the work area."

Change starting today: Everything

After the analysis and definition of the first milestones, the new owner set to work with a will. Walls were torn down in the manufacturing building, machines had to make way for new ones, all documents and furniture were disposed of: changes that aren’t always easy for the employees. "I communicated with the employees a lot right from the start," Buchert stresses. "We hold employee meetings roughly every six weeks. I also go through the company every morning and greet everyone. This gives employees the chance to speak their piece. However, we also have an external business psychologist who holds meetings with employees."

Buchert also introduced improved working conditions: This includes changes like company cars and electric-powered company bikes, improved work materials and more flexible work schedules. New lighting and lifting tools were also implemented in production to improve convenience for employees. "We gained new employees and lost others," says the owner. "Despite this, we’ve always tried to involve the employees. We had at least five barbecues last summer. We do this to celebrate the acquisition of new machines, a process that’s up and running – or just to show that we’re making progress.“

An interim evaluation

Yesterday, today and tomorrow

What’s changed in the company over the last year? What can already be seen today of the future plans? An inventory: First, the production building was remodeled. "In the past, there were partitions between individual work areas, convoluted paths and a feeling of confinement," says Buchert. "We removed walls, moved some machines and configured everything a bit more generously." A CAM office was set up in the middle of the building. Programming was previously done right on the machine using drawings. Now Tebis

software solutions are implemented for 2.5D and 3D programming, and reliable, executable, complete programs are sent to the machines. Buchert explains the switch to Tebis software: "We wanted more than just CAM software; we wanted an end-to-end solution. For us, Tebis is a process provider. As far as I know, they’re the only provider in the industry from which we can obtain consulting, software and implementation from a single source." Another milestone in production is tool standardization. "In the past, the machine operator would often scrounge together the tools he needed," says Buchert. "There were parts that required up to 16 different tools." Now eight tools are usually sufficient. The milling tools that will be used are defined in advance. "Our programming has also vastly improved," the Managing Director says. "We’re now capable of generating runtimes of up to 30 hours in one stretch.“ "First the process, then the software:" Industry expert Jens Lüdtke from Tebis Consulting. (© Hanser/Schröder)

"First the process, then the software:" Industry expert Jens Lüdtke from Tebis Consulting. (© Hanser/Schröder)Using simple tools

And what about planning and control? Lüdtke explains the use of "simple tools" for these processes: "Many people confronted by planning problems make a big mistake. They buy a planning system and think that they’ve have solved the problem. But that's not how it works. The planning philosophy needs to first be integrated in the company. If planning doesn't work with the simplest tools, it's not going to work with software, either." This means that the starting point is always a table in Excel. First the employees have to be brought on board and the philosophy established in their minds step by step.

Walter Formenbau is now at this point in the process. There are tracking cards for every part passing through manufacturing. And hanging next to every machine there’s a whiteboard with a handwritten list of the current orders. Machine data acquisition is starting to be introduced in parallel with this. A small puzzle piece in the large ProLeis manufacturing management system that’s gradually being installed and will lay the foundation for networking the machines. An augmented-reality pilot project was performed for optical quality control: The image of a real part is displayed on a tablet –

superimposed with the CAD data. The user can therefore perform a target/actual comparison: for example, on the part while it’s clamped in the machine.Money has to be made despite the many areas "under construction"

The company can also be proud of its economic situation: Despite large investments, Buchert managed to generate a profit and increase annual revenues to €5.2 million. "We’ve put together a high-performance investment plan," he explains. Over the next five years, we’ll invest over one million Euros every year in setup equipment, machines and software. "And no matter what we do, it has to stay affordable for the company, because we have to make money along the way."

A subsidy from the state of Baden-Württemberg helps a little. Lüdtke, who’s very familiar with the funding opportunities in Baden-Württemberg, prepares the application: "It’s certainly worth the effort. Depending on the project, a company can receive up to €40,000 per year in state funding."

Off to the future!

Finally, we'll take a look ahead: What does the future look like for Walter Formenbau? The team of Buchert and Lüdtke shares a clear common vision: Motivated employees (they aren’t superfluous!) stand in a brightly lit manufacturing building with a white floor and feel very proud to be working in the die manufacturing company of the future. A die manufacturing company where everything is clean and well-organized and where the work is automated and standardized. The software systems are networked together and ensure transparency in planning and manufacturing. It’s also always possible to quickly intervene in the process and respond flexibly to short-term requirements. "I think that the most important elements are functioning processes and motivated employees," Buchert adds. "Everything else can be bought with money."

The article above is protected by copyright. All rights to the article are owned by Carl Hanser Verlag GmbH & Co. KG.

The licensee is granted the non-transferable right to publish the article as digital media on its own websites, by email and on data carriers. Changes or transmittal of this article to third parties outside of the narrow limits of the copyright aren’t permitted.

We wanted more than just a CAM software; we wanted an end-to-end solution. For us, Tebis is a process provider. As far as I know, they are the only provider in the industry from which we can obtain consulting, software and implementation from a single source.

Jens Buchert, Managing Director, Karl Walter Formen- und Kokillenbau GmbH & Co. KG, Göppingen, GermanyOur programming has also vastly improved. We are now capable of generating run times of up to 30 hours in one stretch.

Jens Buchert, Managing Director, Karl Walter Formen- und Kokillenbau GmbH & Co. KG, Göppingen, Germany