-

Croner Präzisionsformenbau: A traditional company trims its sails

Company

Croner Präzisionsformenbau GmbH

Location

Sachsen bei Ansbach, Germany

Focus

Process analysis

Benefits:

- Automated manufacturing process

- Identifying and developing further potential in the company

- Improving employee motivation

Sector

Mold manufacturing

Published

2024

Interviewee: The management team of Matthias and Wolfgang Croner has positioned itself together with the traditional company's strong team for a viable future,

This mold manufacturing company can look back on a long history – and has repeatedly proven its ability to change and renew itself. Croner is a well-known mold manufacturing company with roots extending all the way back to 1685 and is located in Sachsen bei Ansbach in Central Franconia. The two managing directors, Wolfgang and Matthias Croner, took over the company from their father in 1996 and christened it with its present name of Croner Präzisionsformenbau GmbH. Since then, the company has relied on a mix of tradition, forward-looking investment and modern team management. They have also kept an eye on the future and have set their course accordingly with the support of Tebis Consulting. Both currently consider the jointly implemented process analysis as one of the most expedient measures.

The present company headquarters of Croner Präzisionsformenbau is precisely where their grandfather's smithy was located a few decades ago, together with the gas station, the village store and their family's home. This represented a true melting pot for the products and technologies that shaped the area. Brothers Wolfgang and Matthias Croner successively expanded the former smithy to an impressive mold manufacturing company, currently with 30 employees and a broad product spectrum based on precision mold manufacturing, development & design, fixture manufacturing, measuring & test gauges and much more.

Open to feedback

The two managing directors were attuned to the future right from the start: Hierarchies have been kept deliberately flat and corporate management focuses on fairness. They have been open to criticism and to broadening their own perspective and conducted regular status-quo analyses together with their in-house tax and business consultant. Early on, the business managers decided to keep up with the latest technology and to invest in a corresponding production environment.

"We were actually already in pretty good shape," recalls Matthias Croner, "but when we met Tebis Consulting through VDWF, we were immediately impressed by their consulting approach. Jens Lüdtke and his team have a practical background and combine technical industry expertise with effective consulting on an equal footing. We were ready to call on the expertise of these professionals and we have since fully benefited from their many practical recommendations. Both as a team in human terms, but especially from an economic standpoint."

They started with a workshop on the strategy of a mission statement, also focusing on the company's positioning. Then along came Covid. This company was also struck by the dismal outlook for the future of the economy and the industry, but instead of waiting, paralyzed, the managing directors decided to seize the moment and to conduct an in-depth process analysis.

Matthias Croner summarizes: "After the analysis days, Tomek Kawala definitely had a clear understanding of what makes our company tick. His perspective from the outside uncovered even the slightest weakness that we had become habituated to and could no longer see for ourselves. We were even unaware of some bottlenecks; his analysis helped us here to transform our gut feelings to logic and to make reasonable decisions." Tomek Kawala, Tebis Consulting: Responsible consultant in process analysis with Croner Präzisionsformenbau

Tomek Kawala, Tebis Consulting: Responsible consultant in process analysis with Croner PräzisionsformenbauProcess analysis – everything was put to the test

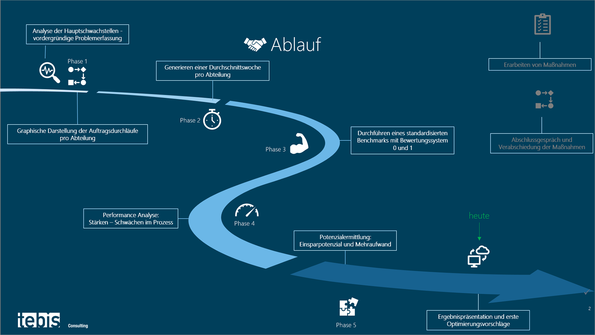

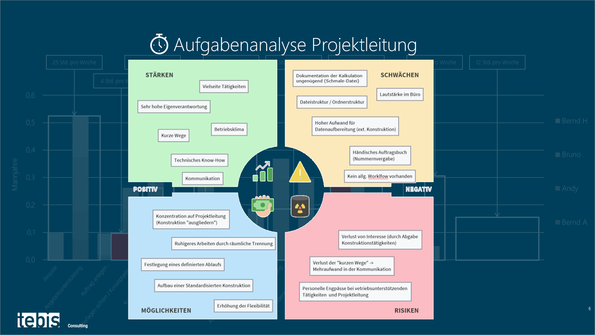

Process analysis with Tebis Consulting: Although the focal points in every customer project have to be determined on an individual basis, every project still includes several typical stages and goals.Tomek Kawala from Tebis Consulting conducted the analysis jointly with the managing directors and with the entire team, also spending several days diving into day-to-day operations. He monitored the processes, tracked times and procedures and peered over everyone's shoulders in every area. He inspected the practical areas – work preparation, CAM programming, machining (milling), EDM and assembly – as well as the procedures and processes in project management. Design activities were put to the test in the same way as technical interactions in production.

Tomek Kawala comments: "A lot of things were not running truly smoothly, and not just at first glance. I was impressed by the technical expertise, the culture of individual responsibility and the short, efficient paths in project management." But from his outside, professional perspective, he was able to identify a series of recommendations for improvement. Above all, Kawala directed his client's attention to a matter that extended across all stages from work preparation to milling: The lion's share of communications were traditionally based on paper and was thus time-consuming, prone to errors and cumbersome.

Matthias Croner states: "We are immensely grateful for Tomek Kawala's precise 360-degree perspective. In addition to digitalization of the previous cumbersome paperwork, new insights on the management level included numerous items, such as the irritating noise level, that were considered minor details but could be easily corrected. Further and more far-reaching insights also resulted. For example, we learned that it was inefficient to simply do our own acquisition along the way. Proactive sales has since become indispensable in our industry. We hired our own sales professional who also has experience from the industry, already has great contacts and who knows our customers' needs inside-out, especially those of OEMs."

The importance of team spirit

Tomek Kawala was also impressed by the collaborative spirit of the production team: A high degree of technical expertise, extensive individual responsibility, and especially, an extremely good corporate climate. Croner's intention to manage the company in a modern spirit of partnership had a tangible impact. Tomek Kawala's additional recommendations with regard to more professional collaboration therefore fell on open ears. The changes are now a part of corporate culture, starting with regular meetings for the entire team and extending to annual appraisal intervals and individually customized training. The company is not suffering from the industry phenomenon of a skilled labor shortage, and continues to successfully conduct its own training.

The production environment and technical orientation – then and now

The production hall that the consultants from Tebis Consulting found was also in line with modern requirements. This was hardly surprising, as Croner consistently follows its commitment to investing new suitable equipment every year. For example, the machinery included a Röders 5-axis machine combined with a measuring machine, various Hermle machines and the ability to work with pallet changers. In short: Measuring, milling and EDM all integrated in automation. The team also uses CAE software to simulate and analyze injection-molded parts. This enables early detection of any potential problem areas and optimization of the manufacturing process.

But even an apparently perfect technical infrastructure like this still harbored some potential for optimization.

Tebis Consulting recommended that Croner digitalize the most important processes. Emphasis was placed on end-to-end standardization and automation, starting from design and continuing all the way to the machine. This proved to be an ideal basis for reducing expenditure and increasing efficiency.Kawala's recommendation to reduce the previously implemented outsourcing of design services and to design at least 50% of the required dies in-house also provided an important impetus. Croner implemented this recommendation and now has an employee of its own for this work.

Now the sails can be retrimmed at any time

Overall, the managing directors now see the company as being ideally positioned – no matter how volatile the mold manufacturing industry may be at present: "Our processes are more structured, more standardized, leaner and more modern. A key improvement on the technical side is the automated manufacturing process. This all results in shorter throughput and idle times, significantly higher machine utilization times and improved quality in our range of services. Team processes have improved from good to their best, and our employees are technically up to date and are highly motivated in their work. And the best: We have questioned our positioning and have improved our self-esteem as a provider. In addition to our existing customer base from the injection molding area, we are currently also approaching providers of visible and optical parts. We are open to what the future holds and we are proceeding with confidence."